Understanding Balance. Why a "nail in the wall" is not a useful measure of balance.

Posted by Gerd F. Bauer on Sep 3rd 2013

Unbalance, what is it?

Only rotors in motion (bodies that are connected to a shaft) have the unique physical property called unbalance. There are three types of unbalance known today they are as follows:

- Static Unbalance is when the center of mass and the center of rotation do not coincide. (not in the same location)

- Couple Unbalance is when there are two unbalance conditions that may have the same magnitude, but their direction may be offset by 180º relative to each other. This can create a wobble in a rotor.

- Dynamic Unbalance is the same as couple unbalance except for the rotor may have infinite unbalances and may be distributed at random along the axis of its rotation.

How is Unbalance detected or measured?

How is Unbalance detected or measured? Static unbalance detection is a measure of gravitational force. This detection method is commonly referred to as static balancing. Couple and Dynamic unbalance detection is a measure of centrifugal force and requires the rotor to be power rotated (spun). This detection method is commonly referred to as dynamic balancing.

What are some examples of rotors that would use static balancing?

The method of static balancing is typically used for single plane rotors that are thin, such as a lawn mower blades, circular saw blades, abrasive cut-off wheels, narrow pulleys,flywheels, impellers, clutches, fan blades, etc

What are some examples of rotors that would use dynamic balancing?

The method of dynamic balancing is typically used for multiple plane rotors or rotors that are very deep, such as motor armatures, drums, turbines, multiple rotors on the same shaft, complex asymmetrical parts, wide car wheels etc.

Why use static balancing for lawn mower blades?

Static unbalance detection is the most economical for servicing and manufacturing lawn mower blades and discs. Dynamic balancing is not commonly used for servicing or manufacturing lawn mower blades because dynamic balancing instruments are very expensive and not required for single plane rotors such as the lawn mower blade.

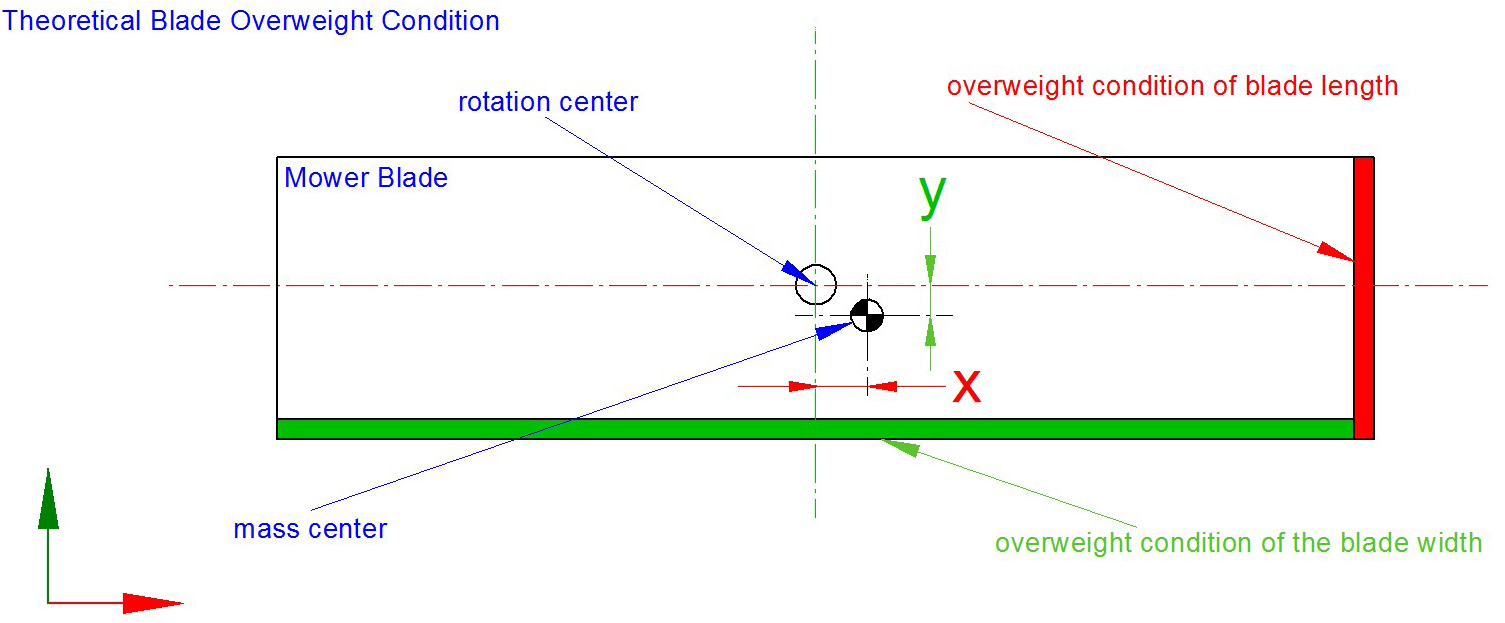

Unbalance in a lawnmower blade is a result of an overweight condition, (caused by manufacturing tolerances, in-homogeneous materials, multiple parts, asymmetric designs, etc.) along the length (RED) and width (GREEN) of the blade as shown in the above illustration. Note: the rotation center and mass center are not at the same location.

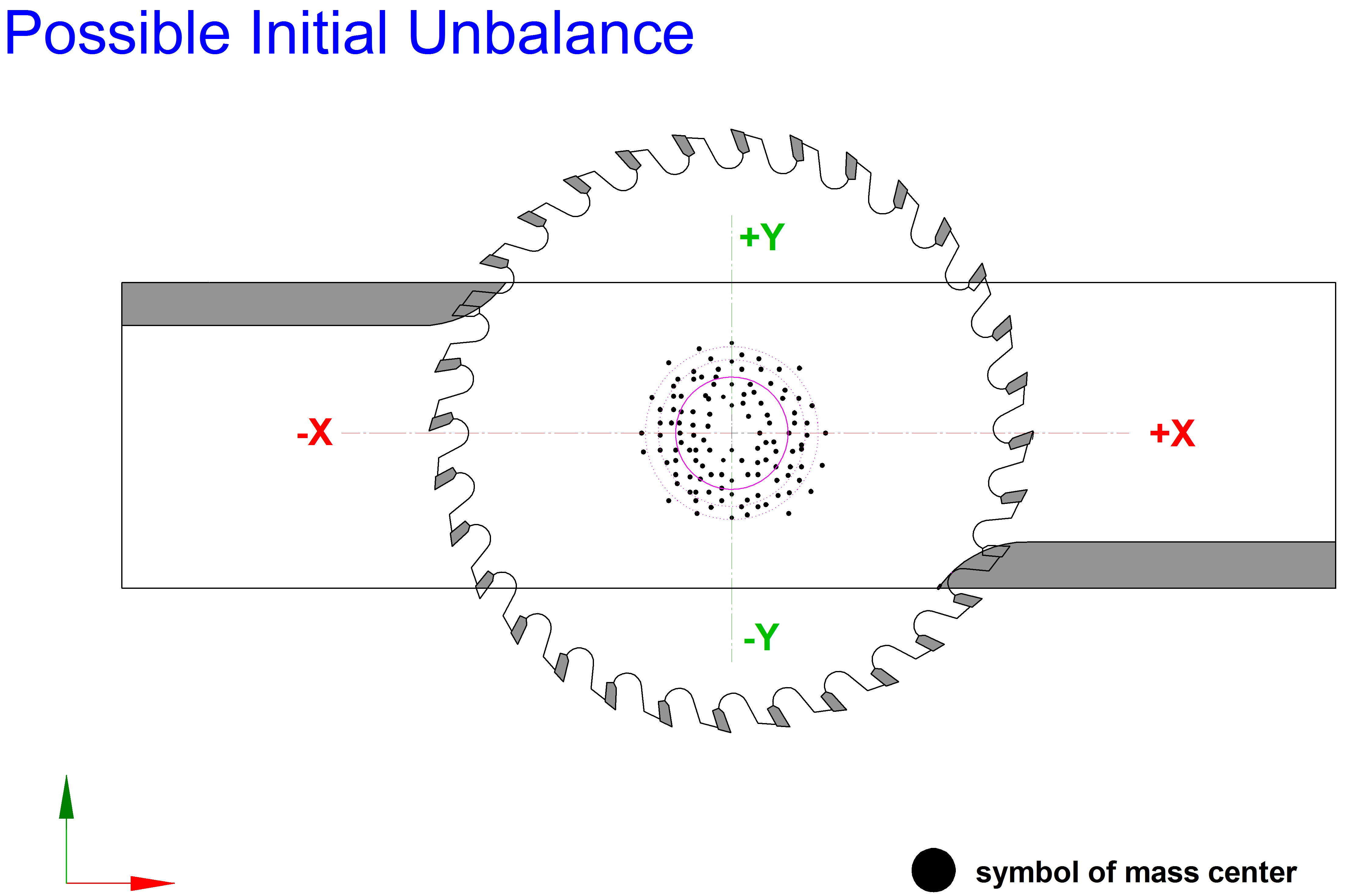

The black dots in the above illustration represent the location of the mass center of different blades or discs after manufacture

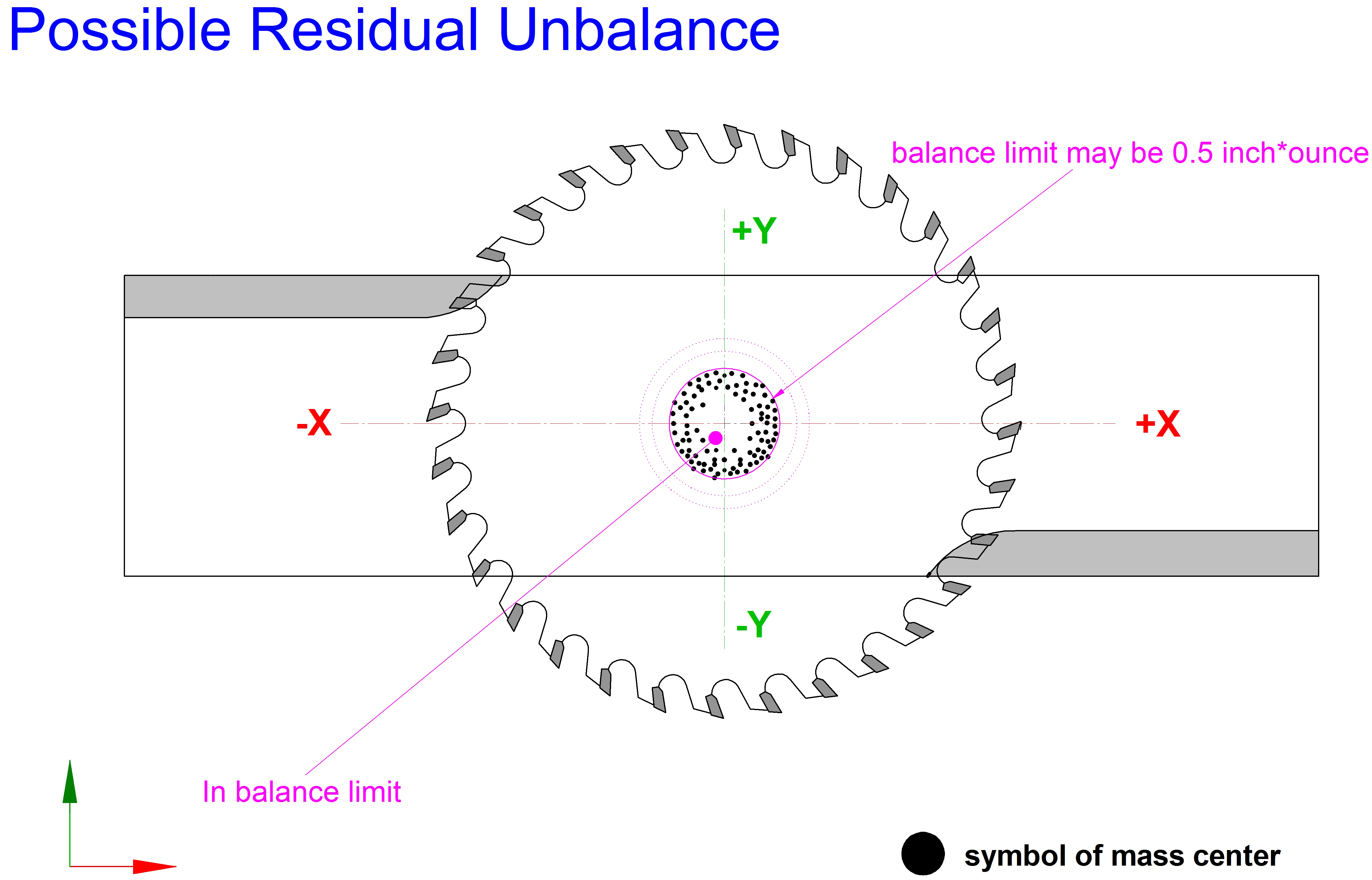

The black dots in the above illustration represent the location of the mass center of different blades or discs after balancing to a specific accuracy

Comparison of the “Nail in the Wall” vs MAG-1000 Blade Balancer.

Only balancing methods that provide fast, accurate, consistent, and understandable readings are useful to serve the industry today.

A test was set up at Magna-Matic Corp. on Sept 12, 2013 by Erik F Bauer and Gerd F Bauer to obtain quantifiable data. Blade number two had the following characteristics:

- It was one of a set of three

- It was worn, used approximately 15 mowing hours, and taken directly off the mower.

- Weight = 3 lbs 4 oz = a total of 52 ounces

- Cut diameter of 24.5 inches

What is the reading on the “Nail in the Wall?”

The blade was carefully located on the nail at the center top of the blade hole and the hands where removed to let gravity act. Result: The blade remained at rest at almost exactly level horizontal indicating that the blade is in balance horizontally.

What is the reading on the MAG-1000 Blade Balancer?

The same blade was placed on the MAG-1000 Blade Balancer in the horizontal position and the hands where removed to let gravity act. The blade quickly started rotating indicating that it is substantially out of balance.

How out of balance is the blade according to the MAG-1000 Blade Balancer?

To balance the blade on the MAG-1000 Blade Balancer it took 7.79 grams = 0.278 ounces at 8 inch from the rotation center to bring the blade into horizontal balance. The blade is 2.24 inch ounce out of balance.

What is the accuracy of the “Nail in the Wall?”

The balanced blade was relocated on the nail in the wall and a test magnetic weight of 6.63 grams = 0.234 ounces started the blade to rotate on the nail and stopped at about 3 inches down from the horizontal. The weight was placed at 11.75 inches from the rotation center. The accuracy of the nail in the wall is 2.75 inch ounce with this blade.

What is the accuracy of the MAG-1000 Blade Balancer?

The balanced blade was relocated on to the MAG-1000 Blade Balancer and a piece of paper measuring 25 by 50 mm (about 1 by 2 inches) that weighed 0.09 grams at 11.50 inches from the rotation center started the blade to turn downward. The accuracy of the MAG-1000 Blade Balancer is 0.037 inch ounce with this blade.

Industry baseline of new lawn mower blade manufacture balance accuracy is 0.5 to 1.0 inch ounce.

Conclusion:

The “nail in the wall” is not a balancing method because it does not provide accurate, consistent, and quickly understandable readings to service a lawn mower blade. The inconsistent readings of the “nail in the wall” in the horizontal position and the substantial inaccuracy 2.75 inch ounce is unfit to bring a blade to the most common industry balance specification. Any balancing method that does not work from the rotation center of the rotor (blade) cannot comply with today’s common balance quality or the balancing quality grades of ISO 1940-1. By definition static balance mass redistribution must be measured from the rotation center.